About the Solar System

Our solar system uses 120 300W ASE photovoltaic panels to form a 2,880

square foot array totaling approximately 36.7kW DC.

Allowing for the power losses in the DC to AC conversion,

the theoretical output of the system is approximately 30.5kW AC.

Taking into account our climate,

we expect to see a more typical summertime

peak production of 27kW. The system is located in Corralitos, California

at approximately

N37o 00'

W121o 47'

at an elevation of 500 ft MSL. It faces about 10o East of

South.

This is about five miles

inland, and is still subject to the marine layer summer fog in the

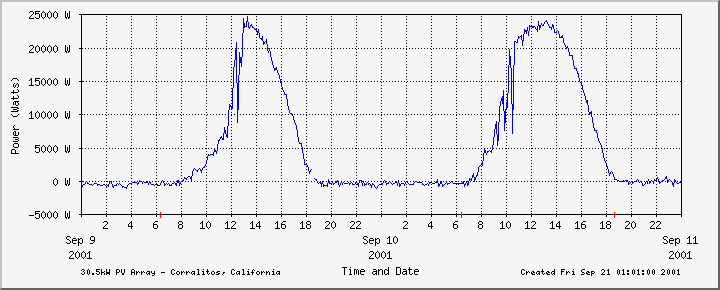

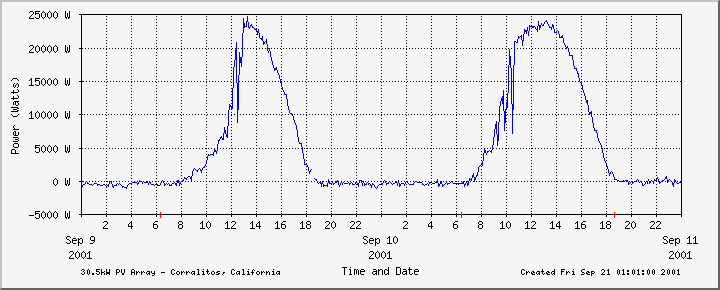

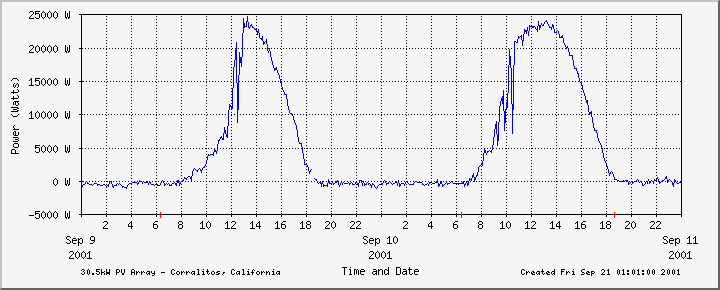

mornings. The following example graph shows the effect of the

morning fog on the output of the system. The fog September 9th

didn't lift until approximately 12:30pm, and the next day the

fog lifted around 10:30.

Click on any of the photographs on this page to see a larger version.

Here are some aerial photographs of the array both during and after

construction. The small 10 by 12 foot

shed located adjacent to the array houses the

inverters and batteries.

The system was

designed and constructed by

the crew that now runs

Full Circle Solar.

Due to the size of the array, a roof top installation was impractical. Further,

we did not want to destroy any of the beautiful (and native) Live Oak trees

that surround our home. These constraints led to situating the array

approximately 600 feet from our home on this south-facing hillside. No

oak trees were harmed in the process.

Situating the array this far from the house led to a number of unique

engineering challenges. We constructed a small shed to house the

batteries and inverters so we could run the higher voltage AC power back

to the house rather than the DC power. The grid side AC power comes

down to the shed in 500MCM copper conductors (almost 1" diameter!)

and the load side AC power returns to the house in three sets of

2/0 copper conductors (about 3/8" diameter). These large wire sizes

were required to keep the resistive losses and voltage drop to a minimum.

Two six inch PVC conduits burried two feet in the ground house this wire.

A third, smaller, conduit carries a Category 5 UTP cable running 10BaseT

Ethernet. This network cable is well in excess of the maximum distance

between repeaters, but the use of high quality hubs on each end and

limiting the speed to 10Mb/sec was a cost effective way of extending

our home's network to the shed for monitoring purposes.

The photovoltaic panels are connected to the batteries and inverters

through a set of Trace C40 charge controllers. Each of the charge

controllers serves approximately 2kW of photovoltaic panel. There are

fifteen charge controllers in all.

In normal operation, these Trojan deep cycle batteries are kept fully

charged. In the event of a power failure, the inverters disconnect

from the grid and use a combination of photovoltaic and battery power

to supply the house. The system is designed with enough battery to

power the home continuously through an extended outage. There are

five banks of eight batteries each, occupying an entire wall in the shed.

The batteries are equipped with "Hydrocaps". These special caps have a

catalyst that recombines the hydrogen and oxygen normally emitted by

the batteries back into water. This minimizes the water use and servicing

required.

The heart of every photovoltaic system are the inverters. These

convert the DC electricity produced by the photovoltaic cells

into AC electricity that can be used by appliances. If more energy

is being produced than I consume at any given time, the excess flows

back into the power grid and I receive a credit on my electric meter.

This system uses three pairs of

Trace Engineering

SW5548 inverters. Each pair services approximately 10kW of photovoltaic

panels.

The brain of the system is this dusty old

FreeBSD server. This

system is connected to each of the six inverters using Trace SWCA

RS-232 interfaces. This system runs the

monitoring and configuration software.

Every few minutes it updates the performance graphs available

at this site.

Note the small Belkin UPS located next to the server. This permits the

inverter to be power cycled under the control of the server without

interrupting power to the server.

This page is supported by

Adelman@Adelman.COM - Kenneth Adelman